In brief

- Diverse challenges across sectors: The oil and gas industry faces various challenges in upstream, midstream, and downstream operations, ranging from operational costs to geopolitical risks

- Technological revolution: Embracing digital transformation, including Agile methodologies and advanced technologies like AI and IoT, is crucial for addressing scalability issues and enhancing efficiency

- Environmental and regulatory concerns: The industry grapples with improving its environmental footprint amidst global climate concerns while navigating stringent regulatory constraints

There’s no doubt about it: The oil and gas industry is a highly competitive field where organizations big and small must make data-driven decisions in order to remain effective and stay competitive.

Usage of oil and gas in our lives is crucial, from transport and electricity and heating, to items like plastics and pharmaceuticals. The world economy as a whole is dependent on gas and oil as energy sources, but how do companies ensure scalability?

Overview of major challenges in the industry

There are a variety of challenges in the oil and gas sector, with threats constantly evolving each year. Due to so much instability and uncertainty, solutions to current problems must not only address what is occurring in the short-term, but how they might answer issues in the long-term, as well.

Operating costs

A major challenge that affects companies in the oil and gas sector is operational costs. For organizations to remain competitive, and be profitable, they must produce their resources and extract derivatives in the most cost-productive way possible. With the constant fluctuations in oil prices along with record inflation rates, cost-reduction strategies have become a big adoption point for companies to ensure their growth and development.

Along with these general operating costs, over time, companies must account for the wear of their equipment, which will inevitably become less reliable, less efficient and more prone to breakdowns as time goes on. Companies can avoid this altogether by maintaining and upgrading critical equipment and systems like measurement equipment, safety systems, radar equipment and pressure systems.

Reducing the environmental footprint

Another major challenge of the oil and gas sector is the need to reduce itsthe environmental footprint. Always a major discussion, the environmental impact of the oil industry on the planet is of high contention, touted as a major contributor to climate change and greenhouse gasses. Fortunately, many major players in the gas and oil industry have recognized the need for change and have already begun making moves to reduce these issues through methods such as decarbonization.

With that in mind, efforts in decarbonization can be greatly assisted through the use of technology, whether in upstream, midstream, or downstream stages. Some of these possible solutions include:

- Electrification

- No flaring through the use of replacing equipment or improving maintenance

- Changing fuel in crude transport ships

- Modifying refinery feedstock from crude to vegetable oil

- Replacing leaking equipment and pipelines

Geopolitical risks

One of the largest geopolitical challenges that has historically affected the oil and gas industry, but specifically so in the past year, has been instability or war in countries where operations are critical. The instability caused by the war in Ukraine, along with changing geopolitical alliances involving Iran, China, Russia, and Saudi Arabia have impacted the flow, consumption, and general future supply of natural gas and oil across the world.

Further, the result of all of these tensions has caused an increased concern for global energy security, especially in Europe, where they are still coping with losing access to Russian gas for industries and households. The digitization of the energy sector as a whole has also made infrastructure vulnerable to cyberattacks.

Technological challenges

When it comes to digitization efforts, the oil and gas sector is facing the immense pressure of quickly trying to adopt the latest technologies and software. A major issue with this is that a lot of the infrastructure most oil and gas companies utilize is fragmented and highly complex. However, this distributed mixture of both modern cloud systems and legacy IT can lead to data that is consistent, hard to interpret, and difficult to understand.

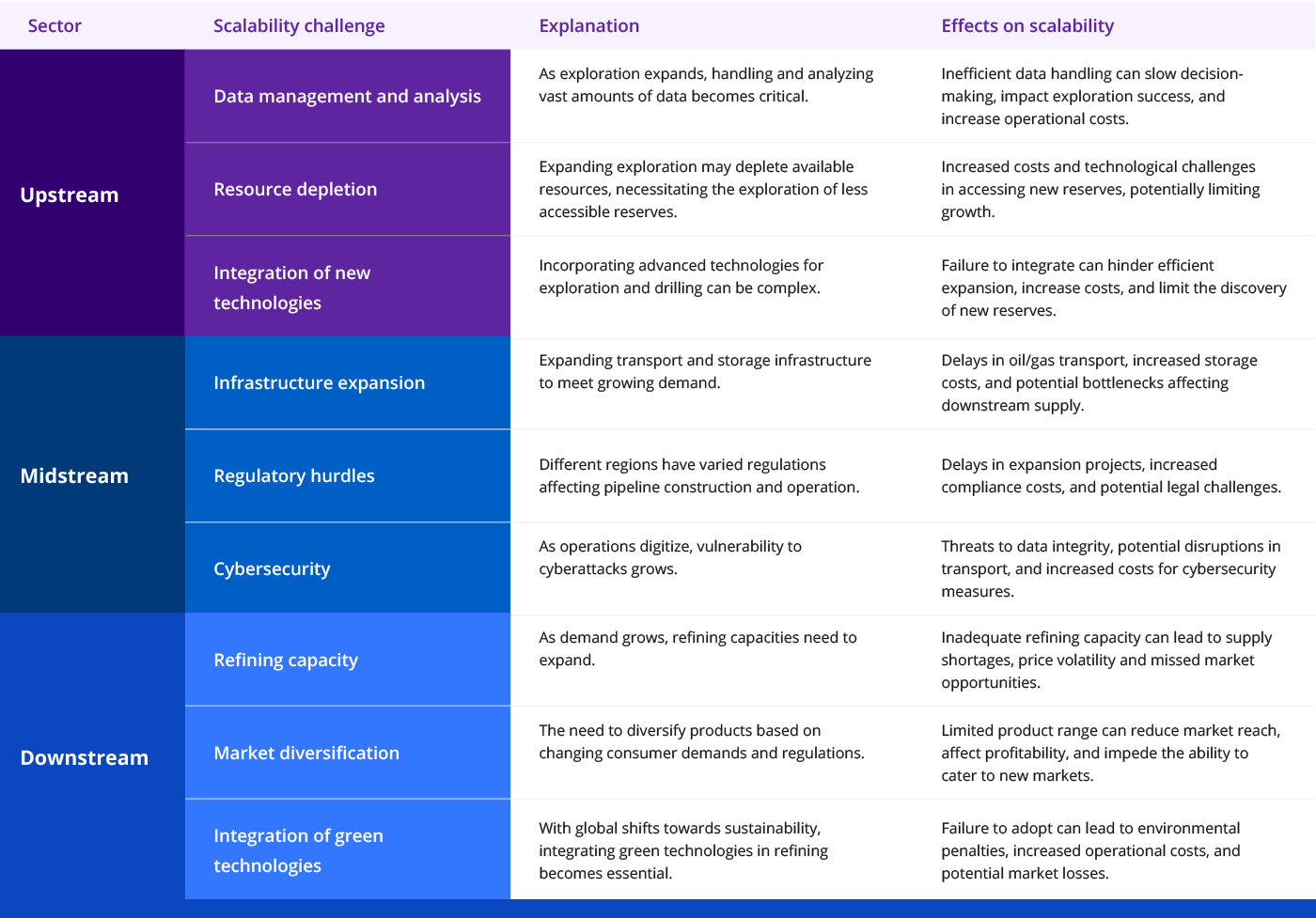

Scalability challenges in the oil and gas industry

Despite all of these challenges for the oil and gas industry, there are still many opportunities to expand and scale. However, each of the major obstacles in scalability’s way have to be analyzed and challenged in order for real change to happen.

Some major issues obstructing scalability include:

- Operational inefficiencies

- Lack of advanced technology

- Regulatory constraints

Operational inefficiencies

As noted, operational inefficiencies can be a major challenge for companies in oil and gas, costing not only time, but money. Should operations be inefficient in exploration, drilling, refining, or transportation, this will also hinder general scalability, due to resources used and expenses charged.

Luckily, the role of technology and the digitalization of this sector is greatly changing the game, allowing for more streamlined processes that can boost efficiency, cut costs, and increase competitive advantage. Automation in oil and gas plays a major part, improving how businesses build pipelines, stay compliant, keep employees safe, and distribute their product.

Lack of advanced technology

Outdated technology greatly contributes to a lack of automation, however, and this can become increasingly frustrating for innovative organizations looking to deploy digital technologies at scale. With legacy infrastructure and IT systems, scaling can be highly limited. Incorporating automation technology can sync all assets and systems across the organization’s field of operations, making monitoring easier and providing a bird’s-eye-view into every aspect of the business.

For key decision makers, it is important to take on the task of digital transformation with a decisive front. Providing evidence of its value to team members will promote buy-in, and encouraging large-scale adoption of digital-first practices will foster new behaviors across all levels. Building digital into the integrated strategy will ensure that new initiatives not only include transformative digital technologies, but that they are also scalable, too.

Regulatory constraints

Before full digital transformation initiatives can come to fruition, it will be crucial for leaders to understand the importance of the heavy scrutiny they’ll face regarding regulatory issues, including safety and environmental regulations. All this red tape can slow down technology adoption and innovation, which can be destructive when trying to gain a competitive edge.

Luckily, there are many strategies available for compliance while maintaining scalability goals. With specific regulatory compliance software, businesses can grow and scale while using their existing consultants, incorporating automated checks and balances within their current processes.

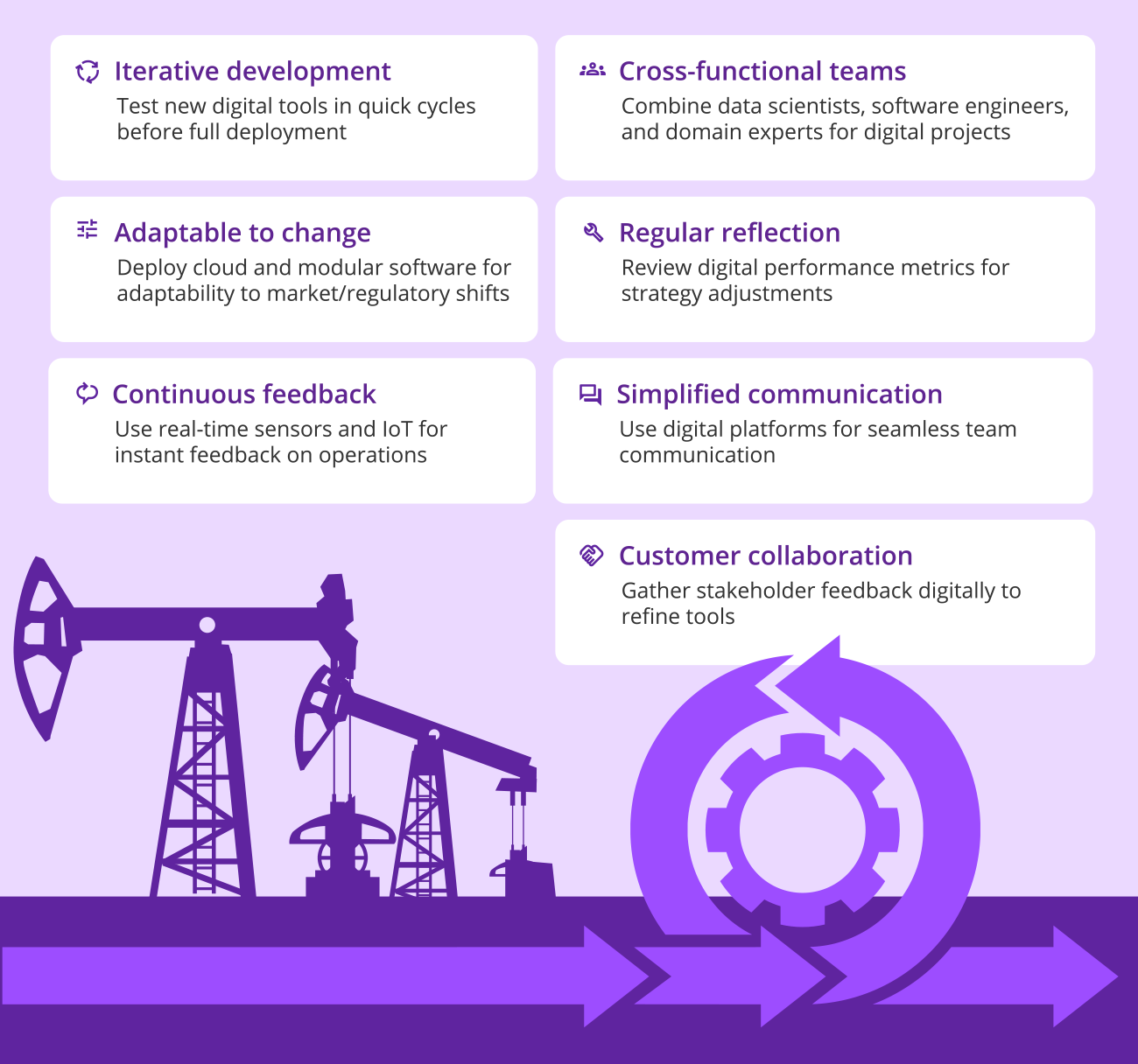

Transitioning to an agile manufacturing model

In general terms, agile means to break things down into smaller tasks and then continuously evaluate how they are going and improve upon them. The agile methodology that many companies are adopting focuses on the importance of assessing and pivoting if necessary, keeping strategies flexible and responding to change as necessary.

In manufacturing, this concept places a strong emphasis on having a rapid response to the customer, viewing both flexibility and speed as a competitive advantage against other organizations. In fields that are quickly evolving, this type of methodology can put a company in a much better position to act on small windows of opportunity as well as demand, whether from customers themselves, or outside factors like policies, equipment, or geopolitical disturbances.

Agile in oil and gas

In a sector like oil and gas, agile manufacturing can assist in a variety of areas, especially in new field development and oil and gas extraction. As these fields continue to rise in demand, with fuel markets rapidly changing and expanding in unprecedented ways, companies in the industry must be able to quickly develop and deliver products to market that not only offer comprehensive support to stay ahead of competitors, but also ensure that existing products are updated with better frameworks and improved features.

Benefits of agile manufacturing for oil and gas

In terms of overall scalability and efficiency, agile manufacturing in fields like oil and gas allow for more flexible supply chains, reduced production times, more efficient and effective operations, decreased costs, and an increased ability to address every-changing customer needs and demands.

As a matter of fact, one industry titan was able to cut $60 million from its logistical costs by establishing a cross-disciplinary team to optimize vessel surveys faster. And another reduced computation time of 3D model rendering by up to 1,000 times over CPU-powered solutions using an agile approach.

The benefits might be stated, but asset-heavy industries have been slow to move. The question is: What are the next steps these giants need to take to transition to an agile manufacturing model?

Transitioning to an agile manufacturing model

For companies that have typically used traditional ways of thinking and working, transitioning to an agile manufacturing model will require specific steps and intentional processes to ensure a smooth shift.

For oil and gas companies, this process usually incorporates six components:

- Current state assessment

- Vision and goals planning

- Implementation

- Digital-led workflows

- Real-time monitoring

- Data analytics and optimization

- Continuous and automated feedback loop

Current state assessment

Before a company can decide where they are going, they must first understand where they currently are. The first step to transitioning to an agile model is to evaluate the current situation and identify any gaps or weak spots with room for improvement. This will allow for quick wins as the processes, products, and services are mapped out and customer feedback is taken into account.

Vision and goals planning

The next step is to plan the vision for this type of switch as well as the goals that should come out of it. Understand what the budget of this switch is going to be, and how much digital transformation and technology adoption can take place. This step will also incorporate the buy-in of major leaders and the introduction to the company of the cultural change needed for agile manufacturing to be successful.

Implementation through digital-led workflows

Digitizing workflows will be a crucial step in transitioning to agile, and it will have a huge impact on processes and typical staff workload. By including automation, there will be faster connections across systems and improved collaboration across disciplines. From cloud and data analytics, to AI and IoT, digital transformation will improve efficiency and increase scalability.

Real-time monitoring

Once remote systems are digital, the next step is to conduct real-time monitoring. Whether for predictive maintenance or improving process performance, this complete overview can provide valuable insights into certain products and ways of doing things. Real-time monitoring can also improve resource utilization and spread knowledge transfer to the current and future workforce.

Data analytics and optimization

With digital technologies comes data analytics, which provides inputs for decisions surrounding anything from performance, maintenance needs, equipment capabilities, and more.

Continuous and automated feedback loop

Taking these data insights into the next stage helps with the continuous and automated feedback loop. Based on the learnings from earlier, leaders can better determine what is working and what areas need improvement, and make quick decisions. This is also a fast way to share key findings with relevant stakeholders, feeding information back into an integrated and evolving plan that is further adjusted and improved upon.

Leveraging technology to overcome scalability challenges

For an organization to successfully address scalability challenges, they will have to adopt certain digital technologies. Some of these might include:

- Artificial intelligence

- Internet of Things

- Data analytics

Artificial intelligence (AI)

One of the first routes to go when incorporating technology to overcome scalability challenges is to adopt AI. AI is typically thought of as beneficial for businesses because it can automate routine tasks, freeing staff up for more critical and complex work.

There are many other ways that AI can be incorporated in oil and gas companies:

- Supply chain management: AI models can quickly help organizations improve their supply chain workflows, from predicting demand to scheduling shipments

- Predictive maintenance: With the help of data from remote monitoring devices, AI can alert when equipment needs to be maintained, and can predict when it’s likely to fail, allowing employees to take proactive measures to fix the issue before it causes downtime

- Safety management: AI models can provide safety insights and predict any potential hazards or safety issues, improving safety management and providing a better work environment for staff

Internet of Things (IoT)

Another major piece of technology that can improve scalability in oil and gas companies is IoT. IoT in the oil and gas industry is defined as the network of physical objects in a company’s ecosystem that are connected to the internet. These types of devices might include equipment, vehicles, buildings, and anything else that is embedded with sensors, software, and electronics. According to some reports, IoT will have an economic impact of $930 billion over the next decade, enabling businesses to closely monitor their remote operations, automate their systems and increase overall productivity.

In terms of scaling, IoT will only contribute to the remote monitoring of systems and the management of resources, allowing better connectivity and more insights into what is occurring in secluded systems. This type of overview into the network will allow staff to be more streamlined and improve efficiencies.

Data analytics

With more connectivity and views into operations, maintenance and systems, real-time insights and data can be derived on the performance of equipment and all systems within the organization. Using this data is necessary for fast and accurate decision making, helping to avoid accidents and keep the business running.

Utilizing an oil and gas software company for custom analytics tools allows oil and gas organizations to comply with stringent regulatory requirements in the industry while also gaining a competitive edge. High transparency and visibility into systems and operations allows for continuous improvement and evolution while scaling, as well.

The future of scalability in oil and gas

The oil and gas companies that wish to scale their business will have to face many challenges. From operational inefficiencies to lack of advanced technology, the pathway to optimal scalability will be full of obstacles that require forethought and decisive action.

In order to adequately address these scalability challenges, leaders will have to make strides to digitally transform their organizations by adopting disruptive technologies and incorporating automation into practices. They will also need to create an agile manufacturing method in order to leverage new and enhanced digital platforms.

By recognizing these challenges and finding solutions to address them, companies in the oil and gas industry can look forward to a bright future where they will thrive sustainably.