In brief

- Record profits and challenges ahead: The oil industry witnessed record earnings in 2022, but it's now at a crossroads with geopolitical, economic, and environmental challenges.

- Digital transformation is imperative: With 70% of oil industry leaders viewing enterprise-wide transformation as essential, technologies like AI, IoT, and AR/VR are becoming central. These tools promise increased efficiencies, cost reductions, and a more sustainable approach to oil extraction and distribution.

- Challenges and opportunities coexist: While the industry grapples with geopolitical instability, environmental concerns, and technological hurdles, adopting advanced digital tools offers a path forward.

As the oil industry strives to keep pace with the rapidly evolving digital era, a host of advanced technologies are shaping its future. With record earnings last year, it will be crucial for these organizations to embrace present technologies in order to ensure success in the outlook for the oil industry.

This article dives into the digital transformation of the oil industry, while addressing its current state, its unique challenges, and the key technologies that will be critical to move forward.

The current state of the oil industry

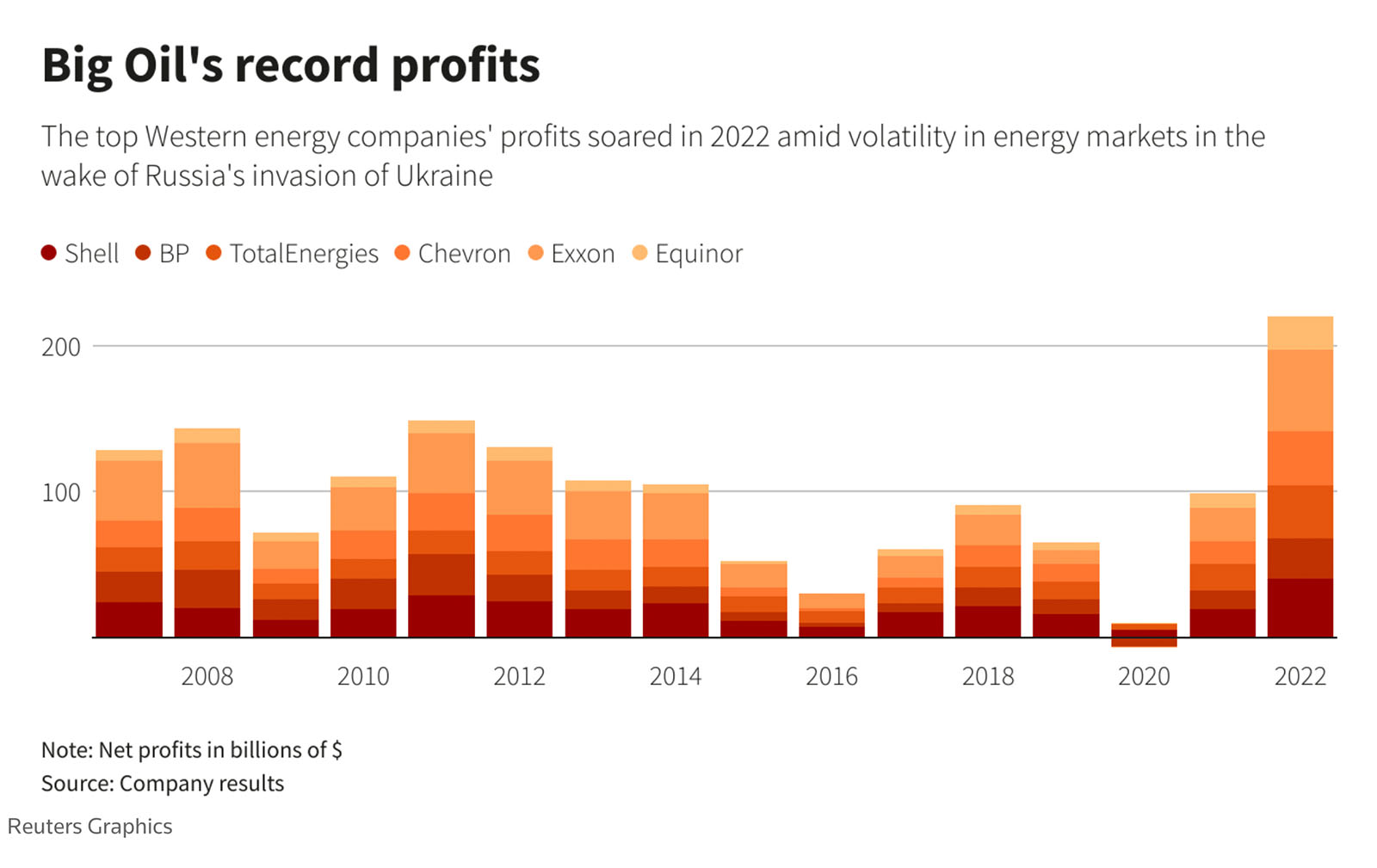

According to Reuters, the global oil and gas industry earned record profits in 2022, allowing organizations to push cash into their 2023 plans and business strategies. Although certain geopolitical and macroeconomic challenges raised some levels of uncertainty, many current trends in the oil industry are offering a positive outlook and new opportunities.

Source: https://www.reuters.com/business/energy/big-oil-doubles-profits-blockbuster-2022-2023-02-08/

Economic uncertainty

While oil and gas are no stranger to price volatility, the current confluence of trade, geopolitical, economic, policy, and financial factors are only further exacerbating issues and leaving the industry in a massive dilemma. While this might currently mean high energy prices for consumers, and record cash flows for oil and gas companies, it leaves the future of the industry in a state of unknowns. As a result of current factors at hand, organizations are beginning to put bigger focus on a balanced energy effort, including low-carbon transition, supply diversification and energy security.

Clean energy policies

Major investors and key stakeholders have noticed the recent higher cash flows, and supportive policies have enabled oil and gas companies to increase investment in clean energy. Overall increases in natural gas investment have been seen, and are predicted to continue into the rest of 2023, including investments that reduce greenhouse gas intensity. In the United States especially, increased volumes of natural gas are being produced in an effort to reduce carbon and methane emissions while exporting incremental supplies.

The digital transformation is already underway

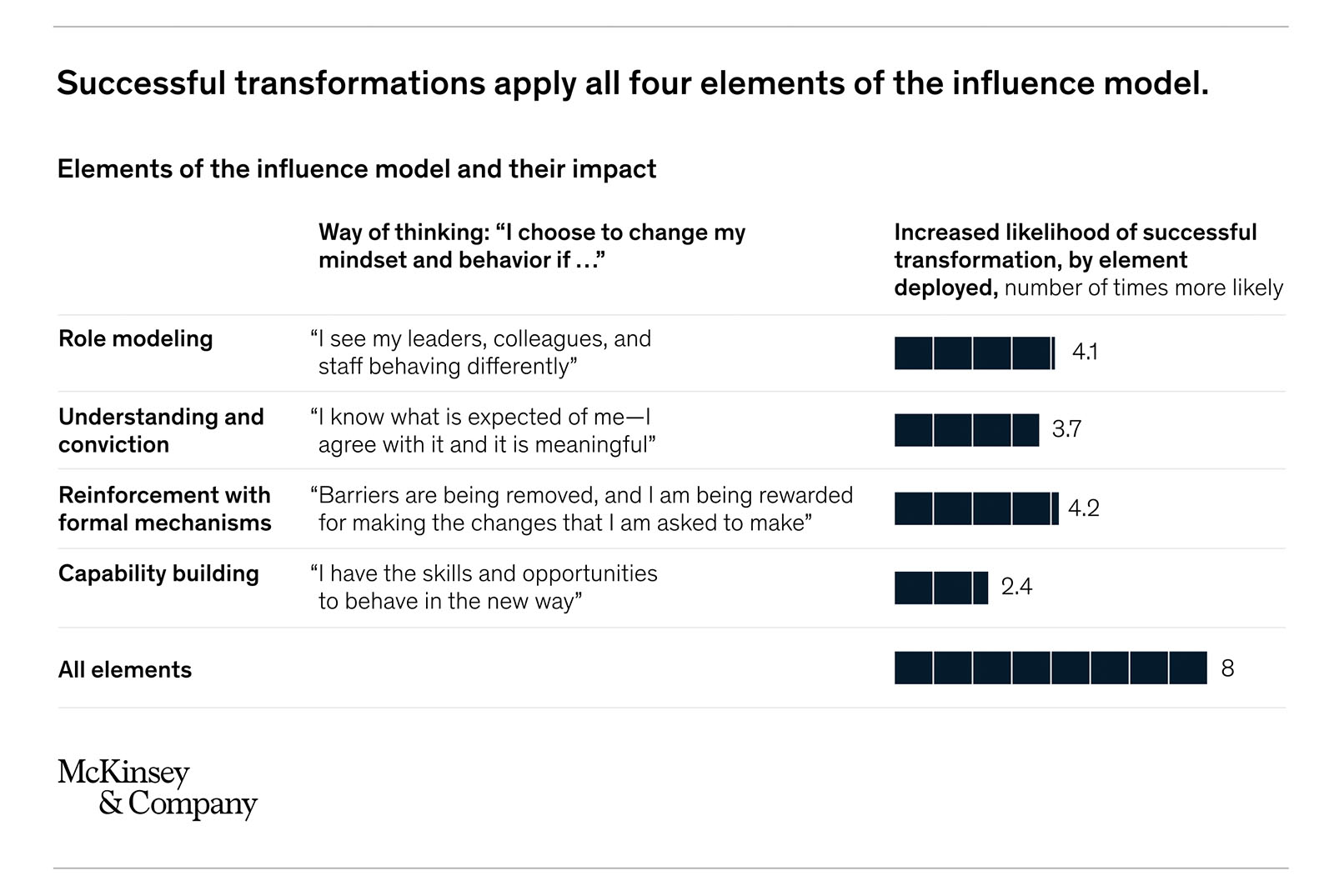

In recent years, digital transformation in oil has become a large focus of the industry, but many organizations struggle with where to begin with this massive undertaking. For the majority of companies, though, beginning the process of digital transformation requires a holistic change in both technology and culture.

According to a recent report by Accenture, 70% of leaders in the oil industry view enterprise-wide transformation as the key to remaining competitive in the landscape. By adapting quickly to market conditions, and embracing evolving innovations, oil businesses can adopt digital tools and technologies across the entire value chain.

There are many benefits to oil digitalization, including boosting output, increasing efficiencies, cutting costs and empowering companies to become more sustainable overall.

A few of the oil industry trends in digital transformation that are already underway include:

- Breaking down data silos

- Implementing advanced analytics

- Establishing strong technology partnerships

- Fostering a forward-thinking culture

Breaking down data silos

One of the biggest ways that many companies are already making progress with digitalization goals is by breaking down data silos. In the past, organizations often spread their data across different departments, which led to many instances of miscommunication and missed opportunities for valuable insights.

By breaking down these data silos, departments are able to integrate data from a variety of sources and make it accessible throughout the entire organization. This approach not only allows for a bigger bird’s-eye view, but it also creates a more cohesive understanding of workflows and operations, ultimately leading to enhanced decision-making and improved cross-department collaboration.

Implementing advanced analytics

Another way that companies are improving their digital transformation is through advanced analytics, which enables the quick analysis of large amounts of data from multiple sources. It then identifies patterns within that data, spots trends, and provides insights for stakeholders to make more informed decisions.

While advanced analytics is highly beneficial, it can be a challenging process that requires a high level of expertise in order to develop the necessary infrastructure and algorithms. With a strong technical team, these analytics initiatives can be carefully planned and orchestrated to maximize benefits.

Establishing strong technology partnerships

By collaborating with specialized partners, leaders in the digital gas industry are further accelerating their digital transformation. With specialties ranging from cloud computing to analytics, these partnerships are bringing expertise to organizations while providing access to other cutting-edge technologies and tools.

Fostering a forward-thinking culture

Last, but not least, many oil enterprises have already begun to adopt a culture of innovation that supports the adoption of digital solutions, including data analytics, artificial intelligence, machine learning, the Internet of Things and blockchain.

Challenges in the oil industry

Although digital transformation efforts are greatly underway, there are many challenges in the oil industry that may delay or disrupt these changes:

- Economic and geopolitical

- Environmental and sustainability

- Technological

Economic and geopolitical challenges

One of the biggest challenges that the oil and gas industry has faced this past year is geopolitical instability as a result of the war in Ukraine along with changing geopolitical alliances that involve Russia, Iran, China and Saudi Arabia. All of these stresses are impacting the consumption, general flow and future supply of oil and natural gas across the globe. Policies between the United States and U.S. Climate/Regulatory have also changed how oil and gas are being developed, while also impacting future developments of renewable energy.

Environmental and sustainability challenges

While the efforts to decarbonize the world’s economies seem to be steaming at full speed ahead, the global competition to control critical minerals and new trade dependencies for resources are already proving to be a challenge for players around the world. With China already commanding significant control over the global supply chain of indispensable materials for clean energy development, these resources could prove to be as fragile and as vulnerable to geopolitical risks as oil and gas have been.

In addition, oil and gas companies are major users of both energy and water resources — both of which result in challenges for the industry; reducing costs, limiting their environmental impact, and optimizing their production yields. These organizations are subject to restrictive environmental standards that only continue to increase, which demands that they rethink their strategies around extraction, production and distribution.

In recent years, the advent of hydraulic fracturing — or fracking — has allowed oil and gas companies to access large stores of oil and gas that had never been available before. This boom in fracking has led to even further environmental restrictions from the Environmental Integrity Project (EIP), bringing lawsuits against facilities for illegal releases to rivers, drinking water and the air.

Technological challenges

Outside of geopolitical and global environmental challenges, the oil and gas industry is also continuously facing the pressure of adapting to fast-evolving technologies and software. The technology infrastructure that most oil and gas companies utilize and rely on is very complex and is typically highly fragmented. This distributed mix of both legacy IT systems and innovative modern systems leads to data that can be difficult to interpret, hard to access and inconsistent in its quality.

While this industry is in much need of digital transformation, progress has historically been slow and inconsistent with poorly executed programs. With extra challenges such as distance and accessibility to equipment, the logistics and financials behind these massive transformation efforts can turn into huge headaches. However, there are many different types of technology available that can assist gas and oil companies with a smooth digital transformation.

Key technologies driving digital transformation

For a digital transformation effort to be successful, there are a variety of technologies that companies can adopt to ensure the process is well thought out, seamless, and aligns with their business strategies and goals.

Digital transformation in the oil industry involves many technologies, including:

- Artificial intelligence (AI) and machine learning (ML)

- Industrial Internet of Things (IoT)

- Automation

- Augmented reality (AR) and virtual reality (VR)

Artificial intelligence and machine learning

Compared to other industries, oil was not an early adopter of AI or ML. Seeing the evolution of the use of these technologies in other sectors, however, has made many leaders in the oil industry realize that things must change in order for them to stay not only competitive, but also relevant.

With that, the uses and applications of AI and machine learning in oil the organizations industry are nearly endless, providing low downsides and huge benefits. From detecting oil well and pipeline leaks, to reducing overall operating expenses, enterprises that are adopting these technologies are seeing massive upsides.

Detecting pipeline and oil well leaks

Although it might be unexpected, leaks from pipelines and oil wells happen frequently, and unfortunately, they can cause large problems. With the use of artificial intelligence oil leak detection, experts can monitor pipelines and oil wells in remote areas and spot potential issues sooner, reducing false positives and preventing damage and loss.

Reducing maintenance costs

Another large application of AI in the oil and gas sector is predictive maintenance. By placing connected sensors on equipment, algorithms are able to learn normal equipment behavior and then flag any abnormalities that pop up. This type of oil field technology helps users reduce costs and avoid any unwanted future outcomes, replacing parts before they fail and proactively upkeeping critical equipment.

Improving safety

When it comes to oil and gas, there is a level of inherent hazards that might be expected, followed by the correct safety procedures. At any point should something go wrong, AI can help keep employees safe in a variety of ways. By improving visibility of the entire system, experts are able to gather information in real-time and be alerted to dangers before it’s too late. Predictive maintenance helps to prevent risks like fires, explosions and toxic emissions by ensuring that proper upkeep is always followed through, and even technologies like AI-powered robots can perform certain tasks that are very hazardous for humans, allowing for empowered oil automation.

Other uses of AI and ML in the oil industry

There are many other ways that AI can be used in the oil industry, including:

- Managing quality control needs

- Streamlining operating models

- Enhancing staff training

- Strengthening cybersecurity

- Handling inspections

- Supporting customer service

- Reducing manual tasks

- Tracking sustainability efforts

- Downtime prevention

- Real-time drilling

- Well testing

Industrial Internet of Things (IIoT)

One of the most disruptive digital transformation technologies in the oil industry, outside of AI and ML, is the Internet of Things (IoT), with an anticipated economic impact of $930 billion over the next decade. In fact, according to a recent survey, many oil and gas companies are already utilizing IoT in their processes, with an additional 20% intending to integrate it into their systems in the upcoming months.

This type of connectivity enables businesses to monitor their operations closely, having a complete bird’s-eye view of their processes, allowing them to automate, increase productivity and decrease costs.

Improved operational efficiency

Devices and sensors found in pipelines, drilling rigs, storage facilities and other critical components can help monitor equipment performance while optimizing processes.

Enhanced decision-making

With the availability of rich data collected by IoT devices, key players can make decisions based on valuable insights, allowing for informed decision-making and strategic planning based on real and relevant information.

Hazard management

IoT technologies can help to detect and prevent potential hazards, including equipment failures, gas leaks and oil spills, allowing experts to intervene and minimize risks to both personnel and the environment.

Smart management

Whether it be IoT-enabled inventory systems that can automatically manage and track stock levels, or real-time location tracking that provides data on vehicles, personnel and equipment, utilizing IoT in overall management systems improves asset monitoring, and ultimately increases efficiency and reduces costs.

Other applications of IoT in the oil industry include:

- Enhanced exploration efficiency

- Smart optimization

- Drilling optimization

- Seismic data analysis

- Real-time monitoring

- Predictive maintenance

- Corrosion monitoring

Automation

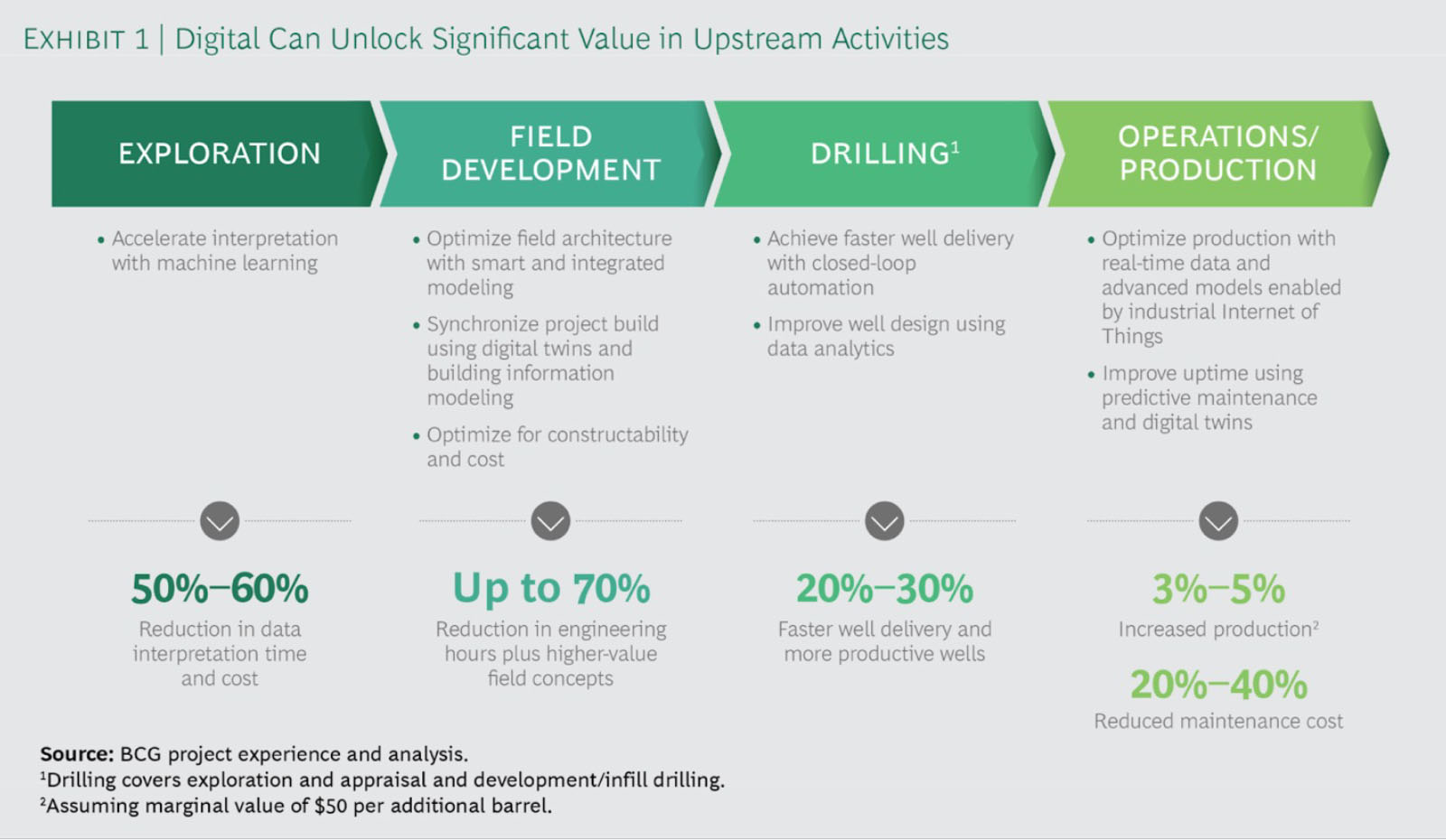

Automation improves the overall process of how companies build pipelines, extract oil, market their product and comply with regulations. A different type of automation, called robotic process automation (RPA), involves software robots that automate the undertaking of mundane and time-consuming manual tasks, allowing workers to focus more on complex situations and problem solving. RPA, often combined with AI, can further automate even more complicated tasks, allowing staff to continue to bring value-driven tasks and strategies to the business.

The benefits of automation:

- Decreased engineering hours

- Reduced maintenance costs

- Lower data interpretation time

- Increased productivity

A study done by BCG in 2019 argues that automation can bring about the following benefits in the oil and gas industry:

Automation in the oil industry has a variety of use cases:

- Cost management

- Real-time pricing

- Pipeline and well monitoring

- Automated reporting

- Regulatory compliance

Augmented reality (AR) and virtual reality (VR)

Although the oil industry isn’t using AR/VR as much as other industries, those that do see success are using it in refineries, particularly in inspections and maintenance. In addition, many oil and gas sites are extremely remote, posing challenges to companies for how to get the required network bandwidth in order to access data.

As far as application are concerned, AR and VRare beneficial for a wide variety of settings across the industry, including training, planning and maintenance.

Staff training

Another use of VR in new oil technology is in staff training. Instead of having to simply study theory in classroom settings, or try to transport students to remote locations, facilities can use a VR headset to help their trainees be in a specific environment and interact with the equipment virtually. This type of training could include virtual rigs, refineries, processing plants and drilling platforms.

Predictive and active maintenance

Both VR and AR can greatly assist in the general monitoring of systems, as well as during the actual maintenance of the equipment itself. VR applications can be connected to sensors that enable engineers to monitor all of the pumps, generators, shale shakers and compressors in real time. This provides an accurate diagnosis of any issues much faster than an in-person inspection, and it greatly reduces the cost.

Once an expert is on-site, AR headsets can clip onto hard hats and project instructions to technicians as they conduct maintenance or inspections of systems. These types of oil information technology animate necessary steps, parts and tools, greatly reducing errors and uncertainty.

Other relevant technologies

Other relevant technologies in digitalization include:

- Blockchain

- Advanced analytics

Blockchain

Although not fully realized yet, blockchain is an additional new technology in the oil industry that could have a major impact in the role of digital transformation.

One of the largest ways blockchain could be utilized is by helping organizations cut down on operational time and expenses while also incorporating more transparency and traceability to the industry. Acting as an immutable digital ledger of economic transactions, this secure cryptographic method is decentralized, meaning it’s not owned by a single entity like a bank, which allows businesses to have a more accurate and transparent overall view of their assets.

Oil and gas companies can also use blockchain in hand with IoT technologies to increase their ability to track devices and to ensure their security, further adding to oil data analytics.

Advanced analytics

Although many companies are beginning to utilize advanced analytics in their processes, the need for it to be an important factor in digital transformation will continue in years to come. Incorporating machine learning and AI into the next chapter with assist in automatically extracting concepts and relationships to find trends and understand their meaning. This will augment human decision-making while shining a light on nontraditional sources of data, such as image, video and audio files.

Incorporating big data analytics can also have a massive impact on the oil industry in terms of enhancing return-on-investment (ROI). In fact, according to a report by McKinsey, advanced analytics has yielded returns amounting 30-50 times the investment within a few months when implemented effectively.

Advanced analytics in the oil and gas industry can have numerous use cases:

- Reducing overall production costs

- Offering predictive and preventative maintenance

- Optimizing upstream oil, midstream and downstream processes

- Ensuring human safety

- Improving offshore operations predictions

Enhancing the present to embrace the future

Accelerating digital transformation in the future of the oil and gas industry will prove to be a process, not simply an overnight fix, but the successful adoption of the above-listed technologies will have benefits beyond what we can even predict.

Whether utilizing VR for training new staff members, adopting AI for real-time data monitoring and predictive maintenance on equipment, incorporating technology into oil well and oil field automation, or bringing in IoT technologies to reduce hazards to personnel and the environment, using digital technologies will not only help oil companies remain competitive, but it will also transform and enhance their infrastructure, increasing their overall value to both customers and the business.

Join Zoreza Global in driving the future of oil and gas with our digital solutions. Get in touch for more information.