Decoupling hardware and software timelines to shorten the development cycle

Jan 26, 2023 by Marek Jersak, Frank Kirschke-Biller and Andreas Lindenthal

Jan 26, 2023 by Marek Jersak, Frank Kirschke-Biller and Andreas Lindenthal

The advent of the software-defined vehicle (SDV) has brought growing complexity of automotive software and a demand for more and more features in a shorter timeframe.

As a result, most automakers are decoupling hardware and software development in a bid to reduce development time, speed up production and ultimately improve economics. Most commonly, we see a push to start testing earlier in the development lifecycle and more virtualization to improve flexibility and scalability in deploying test environments. Hardware/Software separation can go further, but this requires a move away from waterfall-based Automotive Product Development Processes. Zoreza Global helps automakers with this transformation to software-defined vehicles — our unique mix of automotive knowledge and software-development expertise places us in an ideal position to help expand the extent of hardware/software separation and maximize development efficiency.

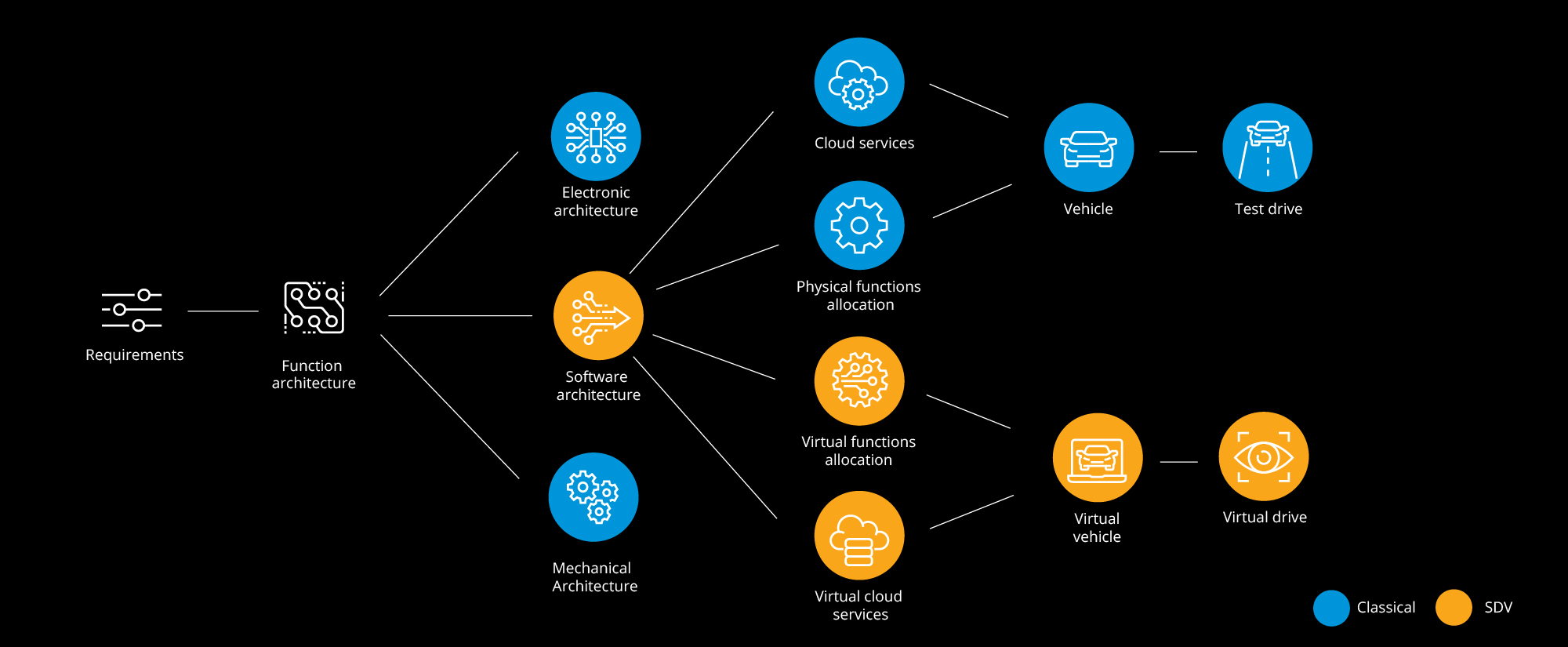

Software/Hardware separation creates a reduction in product development time by decoupling the hardware dependencies from the software development process. This is done by establishing two parallel development processes for software and hardware running at different speeds. However, different hardware/software separation layers bring different advantages. Each of them must be considered:

Cloud automation solutions and the application of CI/CD/CT methodologies have many uses: Scaling up test environments with virtual hardware-targets; providing the needed test capacity for speeding up automated software test case execution; and for achieving high software test coverage in a shorter time. The same applies for virtual ECU integration tests.

Integration time for hardware/software is significantly reduced by focusing on the mandatory hardware/software integration tests and eliminating manual debugging of software on expansive hardware targets or test vehicles. Furthermore, function development is faster-matured and the requirements on hardware are settled earlier:

Software drives hardware development.

The software is developed as a product and additional software milestones must be introduced after SOP deliveries by leveraging OTA capabilities for software updates in the field.

In-vehicle functions — using backend services — isolate in-vehicle software complexity to the cloud backend (with its rich software complexity management capabilities).

Software lives on after SOP, while the substructure of hardware (vehicles) evolves in generations — the vehicle generations always get the appropriate software status. The digital lifecycle process manages and updates this software over its lifetime.

There are many advantages to incorporating hardware/software decoupling right from the beginning by introducing a software-first development approach: